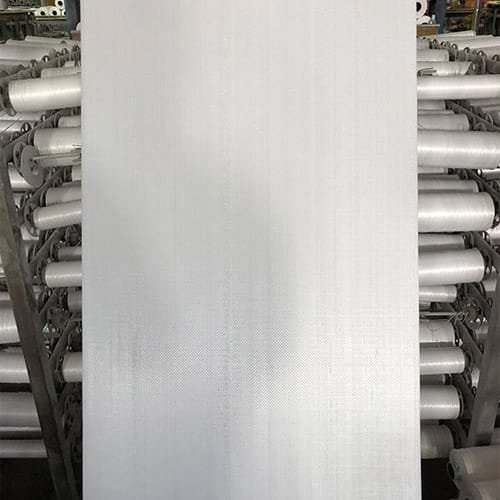

Woven Bags

Polypropylene woven bags for feed, seed and other agricultural and industrial uses have been a specialty of Chengyi for decades. Polypropylene woven bags are naturally tear-resistant, minimizing or eliminating product loss common with other packaging products. Our polypropylene woven bags are made from performance-grade 100% virgin resin, ensuring unmatched strength and durability.

Extra Features

- Premium Quality

- Secure Payments

- Satisfaction Guarantee

- Worldwide Shipping

- Money Back Guarantee

We always keep nearly 100 different specifications of standard polypropylene woven bags in stock. Our stock sizes range from 14”x21” to 38”x70”. For larger custom orders, we can import container load or partial container load quantities of custom polypropylene woven bags.

In-House Custom Printing

Chengyi’s in-house, customized flexographic printing allows you the ability to customize your woven polypropylene feed bags with up to five-color printing. Our trained staff will be more than happy to assist you with your poly feed bag printing needs from the design layout to the final printing plate(s). Contact us to see how ChengYi can help you today!

Production process of plastic woven bags

1. Raw material processing: First, heat and melt the polypropylene or polyethylene granular raw materials, extrude filaments through an extruder, and stretch them into the basic material of woven bags – plastic flat wire after cooling.

2. Weaving process: Weave the stretched flat wire according to a certain warp and weft ratio to form a plastic woven cloth. The weaving density and process parameters can be adjusted according to customer needs to meet the requirements of different strengths and thicknesses.

3. Cutting and forming: Cut the plastic woven cloth coil into sheets according to the specified size, and complete the basic forming of the bag after folding, stitching or heat sealing.

4. Printing: According to customer requirements, single-color or multi-color printing can be performed on the surface of the woven bag to achieve the purpose of brand display or identification.

5. Quality inspection and packaging: The finished woven bags undergo strict quality inspection before leaving the factory to ensure that they meet the standards in terms of pressure resistance and tensile strength, and then are packaged and transported to customers.

Product features of plastic woven bags

1. Lightweight and durable: Plastic woven bags have excellent physical properties, are lightweight, and are easy to transport and carry, but at the same time have extremely high tensile strength and can carry heavier goods.

2. Waterproof and moisture-proof: Polypropylene and polyethylene materials themselves have good waterproof properties. The woven bags can effectively prevent moisture, rain, etc. from eroding the goods, and are suitable for packaging some products that require humidity.

3. Low cost: Compared with traditional packaging methods such as sacks and paper bags, plastic woven bags have a wide range of raw materials, low production costs, and high reuse rates, which meet the requirements of economy and environmental protection.

4. Wear-resistant and durable: Plastic woven bags have excellent wear resistance, and are not easy to break even during long-term use or handling. They are suitable for various complex transportation and storage environments.

5. Strong customizability: According to customer needs, the size, thickness, printing pattern, color, etc. of the woven bags can be flexibly customized to meet the use needs of different scenarios.

Reviews

There are no reviews yet.